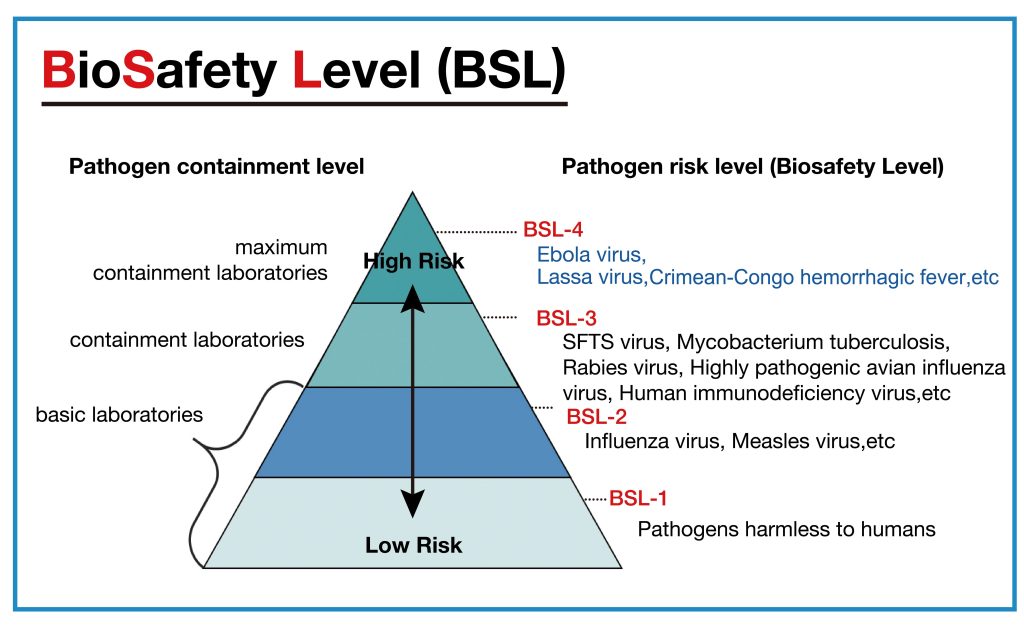

The National Research Center for the Control and Prevention of Infectious Diseases(CCPID) in Nagasaki University aims to contribute to the control of infectious diseases, which pose a major threat to humanity, through research and development. As the research conducted at our center focuses on viruses and other pathogens that are highly pathogenic to humans, we require an experimental facility that has multiple layers of containment measures not to let viruses leak. Viruses and other pathogens are classified into Biosafety Levels 1 to 4 (BSL-1 to 4) according to their pathogenicity. Our center conducts research on viruses and other pathogens up to BSL-4, which are the most highly pathogenic.

The experimental facility at our center is referred to as BSL-4 facility because it include a BSL-4 laboratory. The BSL-4 facility has a high level of containment performance, such as maintaining a lower air pressure inside the BSL-4 laboratory than in the surrounding area. In addition, researchers working in the BSL-4 laboratory wear enclosed suits called Positive Pressure Suits(PPS), which are the first of their kind in Japan.(※)

On this page, we will explain the Biosafety Level (BSL), an overview of the BSL-4 facility, and an outline of the PPS worn when conducting experiments in BSL-4 facility.

(※)At present, the BSL-4 facility building is in the process of being prepared for full-scale operation, and experiments using BSL-4 pathogens have not yet begun.

Overview of CCPID BSL-4 Facility

Biosafety Levels

・The required biosafety level (BSL) for laboratories is determined by the risks associated with a target pathogen, such as transmissibility, pathogenicity and availability of vaccine and treatment.

・ Biological containment measures, both tangible and intangible, must fulfill the BSL requirements.

・ BSL-4 lab oratories are designed for the maximum biological containment and security to facilitate research on high-risk pathogens.

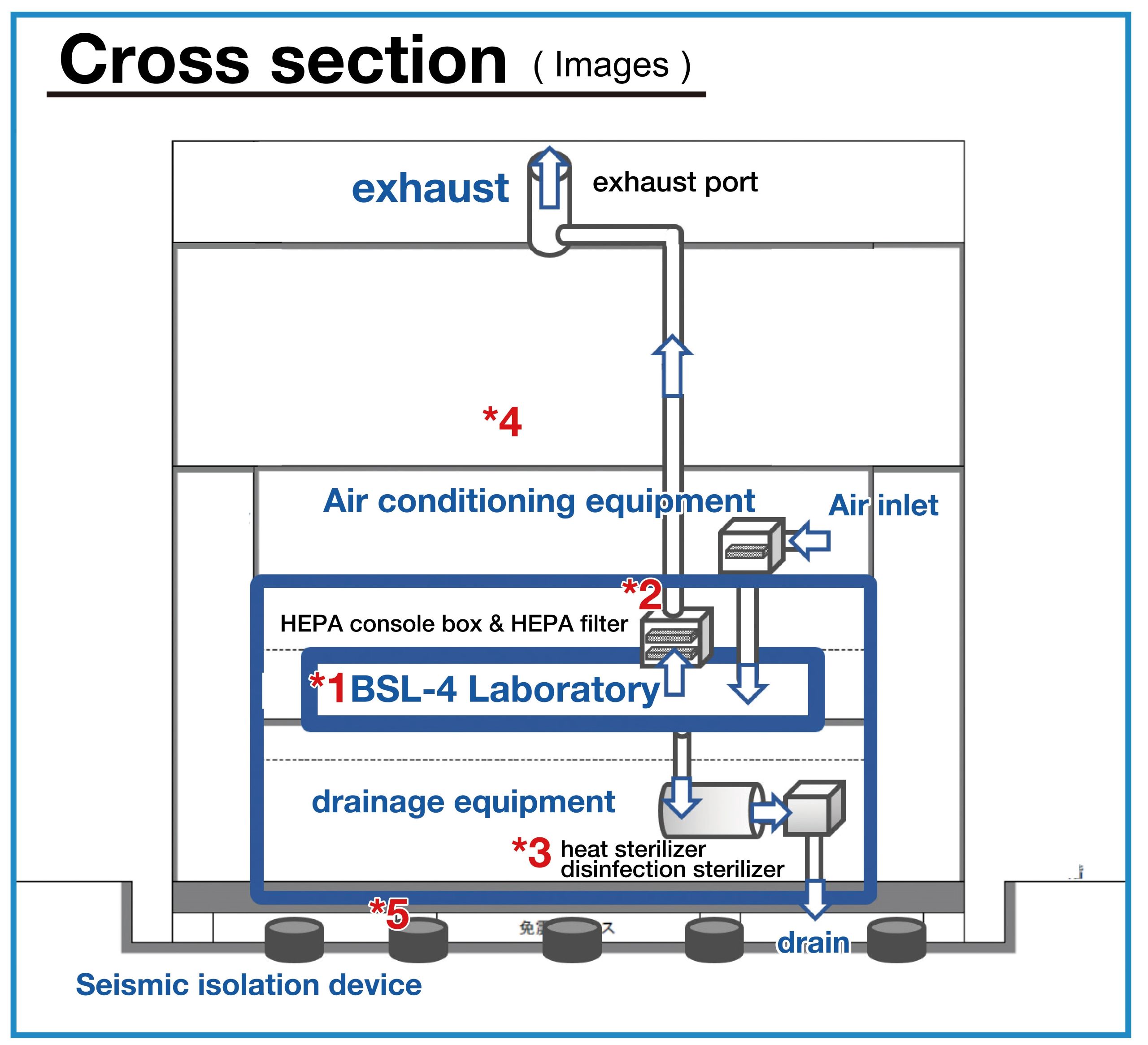

Structure of CCPID BSL-4 facility

*1 The BSL-4 laboratory is structurally isolated from the external environment and enclosed within a fully airtight chamber.

*2 The laboratory is equipped with extensive HEPA filter units for both supply and exhaust air.

*3 Wastewater from the laboratory is fully sterilized beneath the floor through autoclaving and chemical treatment.

*4 The upper floors contain support facilities, such as HVAC (Heating, Ventilation, and Air Conditioning) control systems, backup power supplies, chemical shower tanks, and clean air supply systems for PPS.

*5 The building is constructed on a foundation with high-level earthquake resistance.

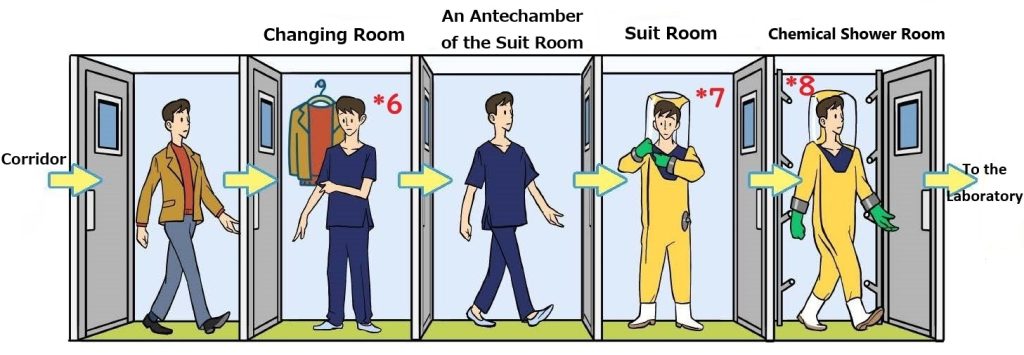

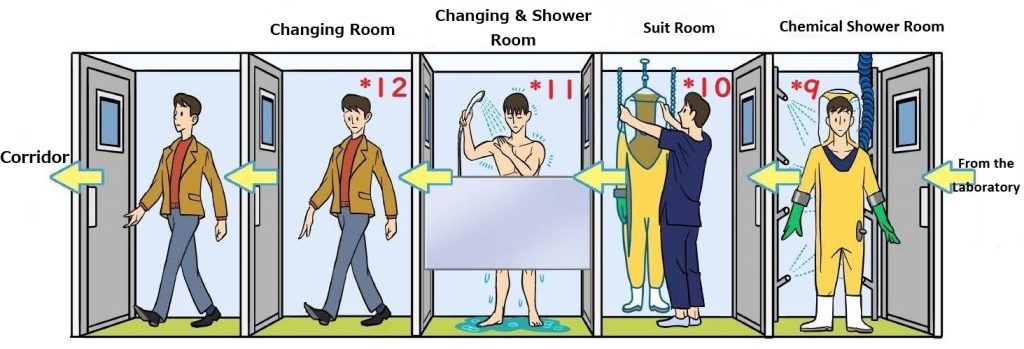

Researchers must pass through several rooms to ensure their safety and security when entering and leaving the laboratory. Safety measures are taken to prevent both researchers and the environment from being exposed to pathogens.

*6 Researchers change from their personal clothes into dedicated laboratory clothing in the changing room.

*7 Researchers put on their PPS suits in the suit room, where clean air is supplied to the suits from an air tank located on the upper floor through connected air hoses.

*8 Researchers enter the laboratory via the chemical shower room (note: chemical showers are not used upon entry).

*9 Researchers exit the laboratory through the chemical shower room, where disinfectant is sprayed from nozzles on all sides for three minutes. This is followed by a warm-water shower for another three minutes to rinse off the disinfectant.

*10 Researchers remove their PPS in the suit room.

*11 Researchers then take a shower to cleanse their bodies.

*12 Finally, researchers change back into their personal clothes in the changing room.

Positive Pressure Suits (PPS) in CCPID BSL-4 Laboratory

Overview of our PPS

・PPS is laboratory wear with an external air supply, suitable for maximum biosafety conditions.

・The PPS physically protects laboratory workers from exposure to pathogens.

・The inside of PPS maintains a higher pressure than the laboratory environment. This positive pressure protects workers from exposure to potentially contaminated air, even if the suit’s integrity is compromised.

・We developed the first domestic PPS for use in this BSL-4 laboratory, in collaboration with Shigematsu Works Co., Ltd, a Japanese manufacturer of safety protective equipment.

①Air Supply Hose

Delivers clean air to workers from outside the laboratory.

②Air Ventilation

Exhausts inner air without allowing backflow from the laboratory environment.

③Face Shield

Protects workers from contaminated splashes while maintain clear visibility.

➃Airtight Zipper

Maintains the airtight seal of the suits.

➄Air valve

Regulates airflow from the air supply hose, ensuring proper suits pressure.

➅Suits filter

Ensures that the air supplied from the hose is contamination-free by a HEPA filter, even though the air is sourced from the outside of the laboratory.

⑦Gloves

Attached at the cuff to maintain the suits integrity.

➇Boots

Bonded to the suits and designed to be slip-resistant.

➈Materials

Waterproof, tear-resistant, and chemical-resistant materials.

【Specifications for Positive Pressure Suits(PPS)】(For size M)

Target height:170cm - 176cm

PPS weight:About 7kg

Air pressure inside PPS:0.4 - 0.8MPa

Air supply volume to PPS:200 - 300L/min

PPSs are available in sizes 3S to 2L.

・Microbiological samples and specimens are handled within Class II Biological Safety Cabinets, which protect workers from contaminated aerosols.

・When exiting the laboratory, workers undergo a chemical shower to decontaminate their suits and prevent any potential leakage of the pathogens from the laboratory environment.